February 18, 2025 by Ingrid Fadelli , Phys.org

Collected at: https://phys.org/news/2025-02-unveils-extrusion-instabilities-viscoelastic-materials.html

Soft viscoelastic solids are flexible materials that can return to their original shape after being stretched. Due to the unique properties driving their deformation, these materials can sometimes behave and change shape in unexpected ways.

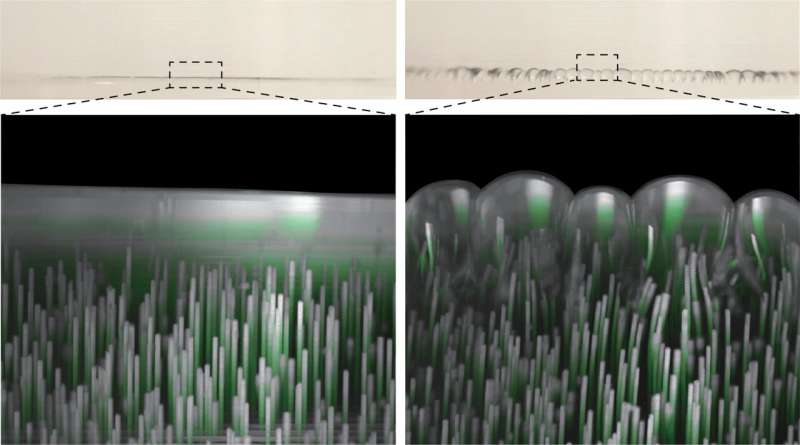

Researchers at Princeton University carried out a study closely investigating the behavior of these materials when they are squeezed through narrow spaces. Their findings, published in Physical Review Letters, show that this extrusion of soft solids through confined geometries results in the formation of instabilities at their surface, characterized by a grooved pattern that deepens over time.

“Soft solids are viscoelastic materials, which have both fluid-like and solid-like features,” explained Prof. Howard Stone, senior author of the paper.

“The fluid-like response is why there is a flow feature to the way the material responds. However, the material itself is described as a ‘soft solid’ because if a shear force is applied to it, after some time deforming (flowing) then it would stop, resembling the behavior observed in other purely elastic materials (solids).”

While conducting unrelated experiments, Jonghyun Hwang, a Ph.D. student supervised by Prof. Stone, accidentally uncovered this new instability that emerged when soft solids were extruded through confined spaces. He thus set out to further investigate this surprising instability, to determine the factors driving their occurrence.

“I first observed this new instability phenomenon by happenstance,” Hwang, Ph.D. student and first author of the paper, told Phys.org.

“The phenomenon we observed drew our immediate attention, as pattern-forming instabilities are highly relevant in engineering and physical sciences. When we first saw this phenomenon, we thought the instability was driven by one of many well-known causes.”

The primary objective of this recent study was to better understand the phenomenon that Hwang had observed by chance. To do this, the researchers also compared it to the emergence of other well-known instabilities in soft solids, which are known to be in great part driven by compressive stresses.

“We noticed, from our previous work, that extremely soft solids can be fabricated, and those soft solids can deform excessively before undergoing fracture,” explained Hwang.

“We used a rheometer, a device that measures various mechanical properties (stress, strain, viscosity, etc.) of soft materials, to characterize our material. The measurements showed that the material is a viscoelastic solid, whose material behavior is solid-like at equilibrium, yet the elastic modulus is ~100,000 times softer than Haribo gummy bears. Our intuition then led us to put the material in a hollow, straight channel and then extrude it through the channel.”

When Hwang, Stone and their colleague Mariana Altomare squeezed a soft solid through a hollow and straight channel, they found that it moved seamlessly and continuously, similarly to how liquids would move. As the material has an elastic feature, however, it stored strain energies while moving, which resulted in its deformation while exiting the channel.

“As we expected, at some point during the extrusion, the surface of the material deformed,” said Hwang. “We observed furrowing trenches deepening as we further extruded the material. To experimentally characterize the instability, we varied the geometry of the channel, gel elasticity, and extrusion speed. However, the measurements showed discrepancies from what other surface instabilities would predict.”

The findings of this paper demonstrate that, just like liquids, viscoelastic solids can be extruded through confined channels. This appears to be the first experimental demonstration of the “flowability” of soft solids.

“We also learned that as these solids flow inside a channel, they undergo shape change on the free surface,” said Hwang. “Our work focused on discussing the fundamental aspect of the phenomenon, to widen our understanding of the soft materials. Therefore, it’s hard to specifically pinpoint where this could be used.”

This recent study by Hwang, Prof. Stone and their colleagues offer new insight into the behavior of viscoelastic materials and their underlying physics. In the future, the team’s findings could open new possibilities for research exploring the behavior of biological soft solids, such as collagen networks and brain tissue, when they undergo significant deformations.

“We observed that viscoelastic liquids also show this instability,” added Hwang. “Therefore, we are now trying to understand the characteristics of the instability with viscoelastic liquids so that we can expand our understanding to a wider class of materials (liquids and solids).”

More information: Jonghyun Hwang et al, Surface Furrowing Instability in Everting Soft Solids, Physical Review Letters (2025). DOI: 10.1103/PhysRevLett.134.058205. On arXiv: DOI: 10.48550/arxiv.2410.14793

Journal information: Physical Review Letters , arXiv

Leave a Reply