December 17, 2024 by Tobias Mickler, Fraunhofer-Institut für Solare Energiesysteme ISE

Collected at: https://techxplore.com/news/2024-12-ai-efficiency.html

Artificial intelligence (AI) helps heat pumps to operate more efficiently, by avoiding incorrect device settings and optimizing system operation. The Fraunhofer Institute for Solar Energy Systems ISE is researching a new generation of smart heat pumps that use artificial neural networks to adapt to environmental conditions and to learn as conditions change.

This increases both energy efficiency and user comfort. Extensive simulations showed promising potential energy savings from 5% to 13% in addition to increased comfort. These results have been confirmed by measurements in an initial field test in a real building.

In the “AI4HP” project, Fraunhofer ISE, together with the company Stiebel Eltron and the French research partners CEA List (Laboratory for Integration of Systems and Technologies) and LPNC (Laboratoire de Psychologie et NeuroCognition) as well as the industrial partner EDF R&D, has gathered important findings on new adaptive control methods for heat pumps based on neural networks.

They focused on the potential, flexibility and practical suitability of AI controls. Up to now, heat pumps for residential heating purposes have mainly been controlled using static heating curves set once during installation.

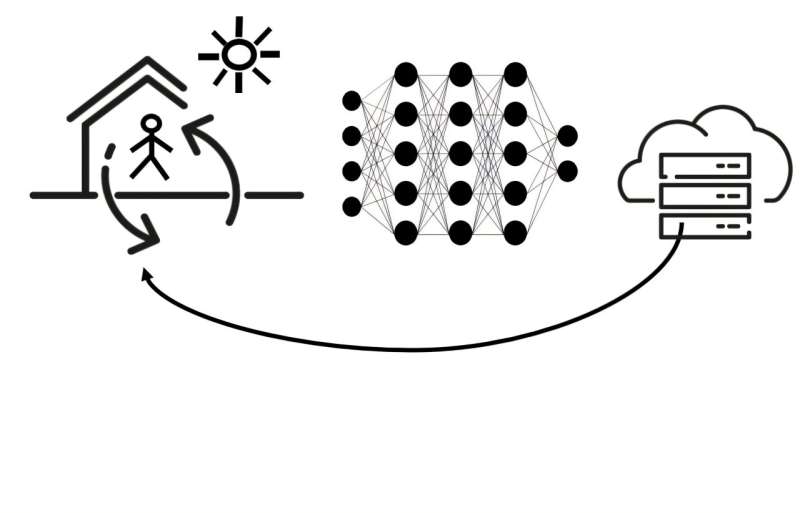

In most cases, the curves have not been optimized for the building, as this is only achievable through a time-consuming calibration. Furthermore, heating curves do not account for short or long-term changes, such as solar radiation, occupant usage or building renovation and aging. In this project, the specific building behavior patterns, e.g., how it changes with varying solar radiation, is learned by artificial intelligence (AI) which continuously analyzes recorded measured values.

“AI methods must become more robust and scalable in order to implement them cost-effectively in a large number of different building types,” says Dr. Lilli Frison, project manager at Fraunhofer ISE. “Furthermore, only reliable and trustworthy methods that guarantee safe operation will be accepted by heat pump manufacturers and their customers,” adds her colleague Simon Gölzhäuser.

Artificial neural networks are able to map complex and highly non-linear relationships very accurately and therefore are suitable for this purpose. Therefore, the research team developed a neural network based on time series prediction within the “AI4HP” project.

The novel transformer architecture was used to enable the network to link historical and future input data and thus be able to estimate the temporal course of the room temperature. The intelligent heat pump controller, developed in the project, uses an artificial neural network to digitally represent the building’s thermal behavior and a real-time capable optimization algorithm to optimally regulate the flow temperature of the heat pump.

Field test confirms positive results

The new AI heat pump controller was evaluated in extensive simulation tests, in which three buildings, each of a different construction year and refurbishment status, were simulated for the period of one heating season. The questions on self-calibration and the adaptability to new environmental conditions were both answered positively.

Depending on the building, the resulting energy savings were shown to be 13% on average compared to the standard heating curve. These savings were due, in particular, to an improved matching of the reference room temperature and the setpoint temperature. Further energy savings can be expected if the controller is extended to include the efficiency characteristics of the heat pump.

On top of this, an initial field test in a real building confirmed the functionality of the new controller. The one-week test operation showed that both the achievement of the setpoint temperature (average deviation reduced by more than half) and the coefficient of performance (COP) improved significantly with the controller. Compared to the reference period, the AI controller recorded a COP increase of 25%, although this needs to be evaluated in more detail during longer field test series and with different building types. Notable is that the algorithm led to the establishment of stable heating curve parameters after just a few days.

Since these parameters are optimized for the specific building, they can be used to increase operation efficiency in systems with conventional heating curves. Despite this great potential, the experience from the field test also showed that a good controller performance requires a high accuracy in the AI building model.

The French project partners within the binational project consortium focused on the optimized operation of hot water heat pumps. The intelligent algorithm for operation optimization was tested in a climate chamber as part of a hardware-in-the-loop laboratory test using a real heat pump and a real consumption profile. The results suggest that the AI prediction in combination with optimized heat pump control has the potential to reduce electricity consumption for hot water supply by up to 8%.

Leave a Reply