September 23, 2024 by Pacific Northwest National Laboratory

Collected at: https://techxplore.com/news/2024-09-alternate-approach-fabricating-steel.html

Potential fusion power plants require materials capable of withstanding extreme conditions. Oxide dispersion strengthened (ODS) steel represents a top candidate material, but current production is labor and cost intensive.

Producing ODS steels has typically required forming a bulk material, followed by a complicated series of rolling and thermal treatment steps to reach a plate or sheet of steel. The numerous steps and complex nature procedures often lead to a final product with nonuniform microstructures, undependable physical properties, and high costs.

The potential for ODS steel applications in future fusion plants has led to research interest in identifying alternative manufacturing routes to produce these materials.

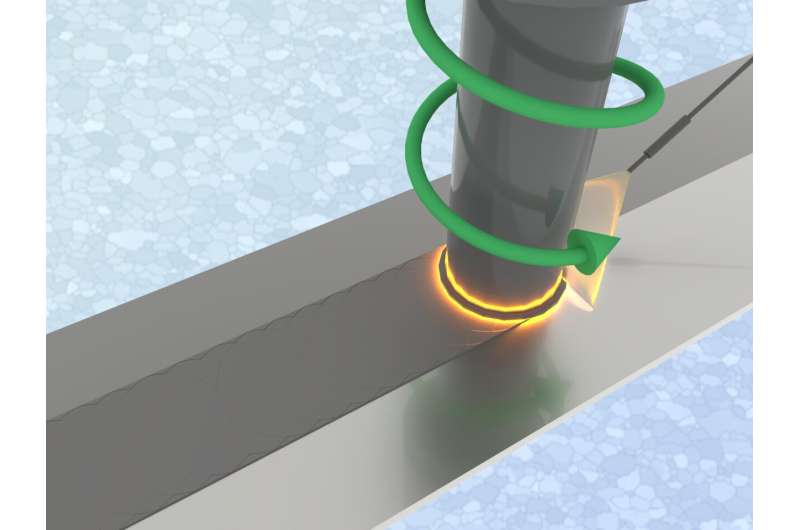

Researchers have now developed a new approach to creating ODS steel plates by combining cold spray deposition and friction stir processing. The work is published in the Journal of Nuclear Materials.

Cold spray deposition uses powder prepared by gas atomization reaction synthesis directly, with no prior ball milling steps necessary. After initial formation, friction stir processing then consolidates the slightly porous material and refines the microstructure.

In-depth analysis revealed a fully dense final ODS steel with a favorable trade-off between strength and ductility. Examination of the microstructure showed a significant density of nano-sized oxide particles, which are known to strengthen ODS steel plates.

Initial work exploring the scalability of the new process is promising, providing a proof-of-concept for fabricating ODS steel through a significantly more straightforward process that should lead to lower overall manufacturing costs and higher-quality materials.

More information: Xiang Wang et al, Manufacturing Oxide Dispersion Strengthened (ODS) steel plate via cold spray and friction stir processing, Journal of Nuclear Materials (2024). DOI: 10.1016/j.jnucmat.2024.155076

Leave a Reply