By Amit Malewar 17 Aug, 2024

Collected at: https://www.techexplorist.com/new-synthesis-technique-promises-faster-more-sustainable-manufacturing/87344/

James Tour’s lab at Rice University has developed a groundbreaking method called flash-within-flash Joule heating (FWF), poised to revolutionize the synthesis of high-quality solid-state materials. This innovative process drastically reduces production time and energy consumption while also minimizing harmful byproducts.

With FWF, gram-scale production of diverse compounds can be achieved in seconds, leading to more sustainable manufacturing practices by cutting energy, water usage, and greenhouse gas emissions by over 50%.

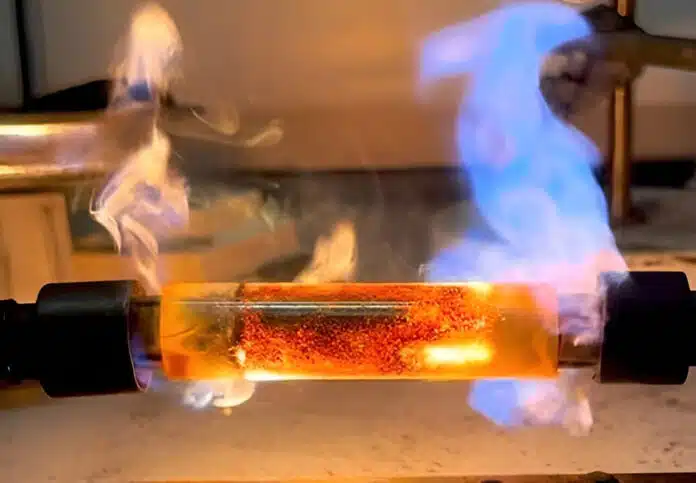

The groundbreaking research expands on Tour’s 2020 breakthrough in waste disposal and upcycling applications using flash Joule heating. This innovative technique rapidly heats moderately resistive materials to over 3,000 degrees Celsius (over 5,000 degrees Fahrenheit), transforming them into valuable substances.

“The key is that formerly, we were flashing carbon and a few other compounds that could be conductive,” said Tour, the T.T. and W.F. Chao Professor of Chemistry and professor of materials science and nanoengineering. “Now we can flash synthesize the rest of the periodic table. It is a big advance.”

By devising the innovative Flash Spark Plasma Sintering (FWF) technique, our team has successfully addressed the limitations of traditional flash Joule heating methods. Using an outer flash heating vessel filled with metallurgical coke and a semiclosed inner reactor containing the target reagents, FWF is capable of generating intense heat of about 2,000 degrees Celsius. This high heat rapidly converts reagents into high-quality materials through efficient heat conduction.

The novel approach enables the synthesis of over 20 unique, phase-selective materials with exceptional purity and consistency. FWF’s versatility and scalability make it an ideal choice for producing next-generation semiconductor materials like molybdenum diselenide (MoSe2), tungsten diselenide, and alpha-phase indium selenide, which are traditionally challenging to synthesize using conventional techniques.

“Unlike traditional methods, FWF does not require the addition of conductive agents, reducing the formation of impurities and byproducts,” Choi said.

This breakthrough unlocks exciting prospects in electronics, catalysis, energy, and fundamental research. It also provides an environmentally friendly alternative for producing a diverse array of materials. Additionally, FWF has the capability to transform entire industries, such as aerospace, where materials like FWF-manufactured MoSe2 showcase exceptional performance as solid-state lubricants.

“FWF represents a transformative shift in material synthesis,” Han said. “By providing a scalable and sustainable method for producing high-quality solid-state materials, it addresses barriers in manufacturing while paving the way for a cleaner and more efficient future.”

Journal reference:

- Chi Hun ‘William’ Choi, Jaeho Shin, Lucas Eddy, Victoria Granja, Kevin M. Wyss, Bárbara Damasceno, Hua Guo, Guanhui Gao, Yufeng Zhao, C. Fred Higgs III, Yimo Han & James M. Tour. Flash-within-flash synthesis of gram-scale solid-state materials. Nature Chemistry, 2024; DOI: 10.1038/s41557-024-01598-7

Leave a Reply