July 30, 2024 by National Research Council of Science and Technology

Collected at: https://techxplore.com/news/2024-07-advances-cathode-composite-sulfide-based.html

Researchers in Korea have united to tackle the challenges in the commercialization of all-solid-state batteries. The work is published in the journal Energy Storage Materials.

Dr. Yoon-Cheol Ha from the Next Generation Battery Research Center of KERI collaborated with a team led by professor Byung Gon Kim of the Department of Applied Chemistry, Kyung Hee University, a team led by professor Janghyuk Moon of the School of Energy Systems Engineering, Chung-Ang University, and others, to develop a technology to optimally mix cathode materials for all-solid-state batteries with sulfide solid electrolytes.

All-solid-state batteries are gaining attention as a next-generation battery technology due to their extremely low risk of fire or explosion. However, they require significantly more advanced technology compared to conventional batteries based on liquid electrolytes, given the solid characteristics of the all-solid-state battery, making manufacturing more challenging.

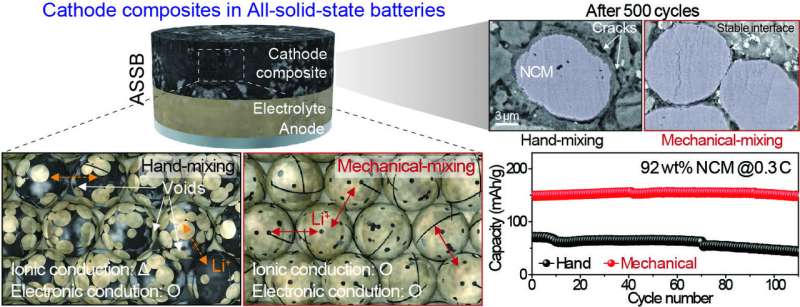

In particular, the effective mixture and dispersion of cathode active materials with solid electrolytes, conductive additives, and binders are known to be among the challenges in manufacturing a composite electrode.

Stringent conditions must be met, such as creating channels (pathways) that facilitate the efficient transfer of electrons and lithium ions and ensuring low interfacial resistance on the cathode-electrolyte interfaces.

Up until now, two main methods have been used to mix cathode materials and solid electrolytes: simply mixing them mechanically in wet or dry conditions to make the thickness of tens to hundreds of micrometers (one millionth of a meter), or using the core-shell structure method, where the surface of cathode materials is wrapped with solid electrolyte.

However, these existing methods have faced challenges in ensuring movement of electrons or ions and in forming a low-resistance interface.

In order to resolve the issue, KERI and university research teams utilized the method of partially coating the cathode active materials with solid electrolyte.

Since sulfice solid electrolyte is sensitive to oxygen and moisture and can deteriorate if misused, the research team developed a blade mill-a special equipment that can utilize inert gases that do not cause chemical reactions. This allowed them to study various types of solid electrolyte coating structures and test and verify the optimal mixture ratio and process conditions with cathode active materials.

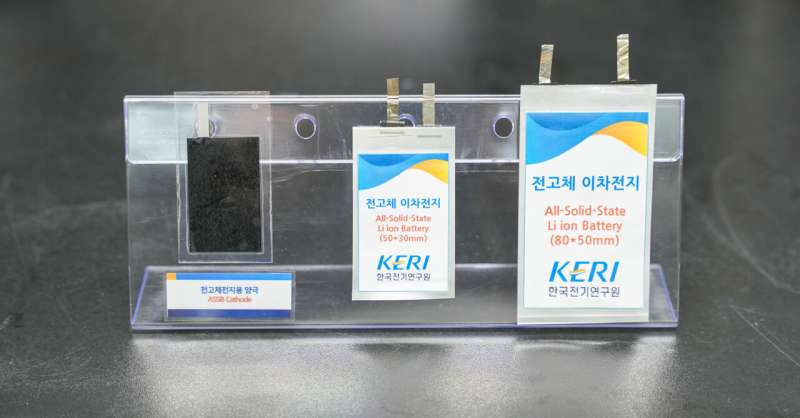

The team conducted various simulations to gather extensive data demonstrating the improvement of the active material utilization (actual capacity compared to theoretical capacity) and rate capability (fast charging/discharging compared to low current charging/discharging). They then applied the result to a prototype (pouch cell) to verify the performance of the all-solid-state battery.

Dr. Yoon-Cheol Ha said, “For the widespread adoption of all-solid-state batteries, it is important to enhance the performance and reduce the cost of the solid electrolyte itself. However, structural design and manufacturing process technologies that effectively create a composite electrode to facilitate the smooth flow of ions and electrons effectively are also important.”

He added, “By using a composite material where the cathode active material is partially coated with solid electrolyte at an optimal ratio, we can enhance the functionality of the electrode and significantly improve the performance of all-solid-state batteries.”

KERI, which has secured patents related to the technology, plans to find potential customers and pursue commercialization, believing that the achievement will attract significant attention from manufacturers of materials and equipment for all-solid-state batteries.

More information: Yoon Jun Kim et al, Exploring optimal cathode composite design for high-performance all-solid-state batteries, Energy Storage Materials (2024). DOI: 10.1016/j.ensm.2024.103607

Leave a Reply