November 8, 2024 by Ingrid Fadelli , Tech Xplore

Collected at: https://techxplore.com/news/2024-11-electrochemical-regeneration-bicarbonates-carbon-capture.html

While systems that can generate energy from renewable sources are becoming increasingly widespread, it might take a while before these systems fully replace solutions that rely on the burning of fossil fuels. In the meantime, researchers have been trying to develop technologies that could mitigate the adverse effects of carbon emissions on the climate and environment on Earth.

In recent years, carbon capture has emerged as a promising solution for reducing the presence of greenhouse gases, particularly carbon dioxide (CO₂), in the atmosphere. As suggested by its name, carbon capture entails capturing the CO₂ emitted by industrial plants and other human activities to subsequently store it underground or re-purpose it.

While several carbon capture systems have been introduced over the past few years, most are either too expensive or too energetically demanding. These challenges have so far limited their commercialization and widespread deployment.

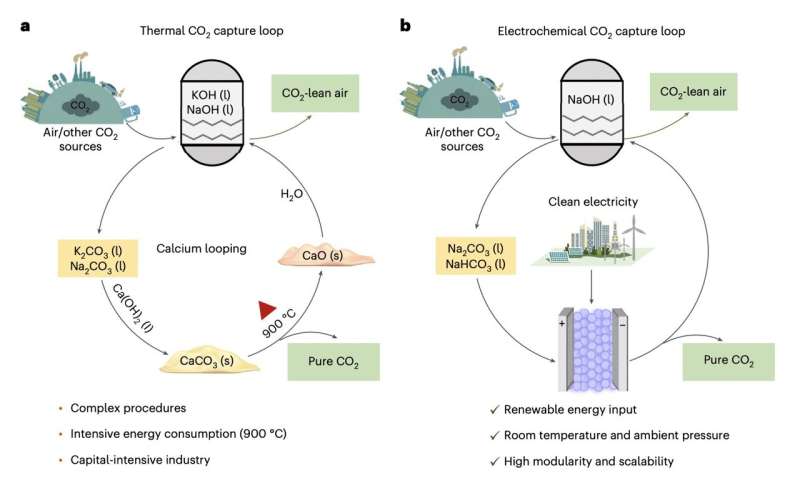

Researchers at Rice University recently introduced a one-step approach to realize the electrochemical regeneration of CO₂ from carbon-containing solutions, which is typically the most energy-intensive step completed by carbon capture technologies. Their paper, published in Nature Energy, could open new exciting possibilities for the energy-efficient capture of CO₂ at industrial sites, which could in turn contribute to the reduction of air pollution on Earth.

“Conventional carbon capture technologies typically consume substantial amounts of heat and involve multiple steps for regeneration,” Xiao Zhang, Zhiwei Fang and their colleagues wrote in their paper. “We demonstrated one-step electrochemical regeneration of CO2 and alkaline absorbent from carbon-containing solutions in a modular porous solid electrolyte (PSE) reactor.”

The researchers showed that (bi)carbonate solutions can be continuously converted back into highly pure CO₂ gas via hydrogen evolution reaction and hydrogen oxidation reaction (HER/HOR) redox electrolysis. This process was demonstrated using a modular solid electrolyte reactor.

“By performing hydrogen evolution and oxidation redox reactions, our PSE reactor selectively split NaHCO3/Na2CO3 solutions, which typically come from air contactors after CO2 absorption, into NaOH absorbent in the catholyte and high-purity CO2 gas in the PSE layer,” wrote Zhang, Fang and their colleagues. “No chemicals were consumed and no by-products were generated.”

The modular solid electrolyte reactor developed and used by this research team was found to regenerate high-purity CO₂ from (bi)carbonate solutions efficiently. In initial tests, the reactor demonstrated a high Na+-ion transport number (~90%), a high capture capacity retention (~90%) and low energy consumptions (50 kJ molCO2−1 at 1 mA cm−2 and 118 kJ molCO2−1 at and 100 mA cm−2).

Notably, the reactor was also found to retain its stability after operating for over 100 hours. These encouraging results highlight the potential of the team’s proposed method for CO₂ regeneration, suggesting that it could be a promising alternative to conventional thermal regeneration processes.

“We achieved industrially relevant carbon regeneration rates of up to 1 A cm−2 (~18 mmol cm−2 h−1), highlighting the promising application potential,” wrote the researchers.

This recent study by Zhang, Fang, and their colleagues could inspire other teams to test this alternative CO₂ regeneration method and its potential for improving the energy efficiency of carbon capture technologies. As part of their future research, the researchers plan to scale up their reactor while also improving its design to attain even better results.

More information: Xiao Zhang et al, Electrochemical regeneration of high-purity CO2 from (bi)carbonates in a porous solid electrolyte reactor for efficient carbon capture, Nature Energy (2024). DOI: 10.1038/s41560-024-01654-z.

Journal information: Nature Energy

Leave a Reply