November 4, 2024 by Bob Yirka , Tech Xplore

Collected at: https://techxplore.com/news/2024-11-blade-coated-perovskitesilicon-solar-cell.html

A team of engineers and materials scientists at King Abdullah University of Science and Technology, in Saudi Arabia, working with a colleague from Helmholtz-Zentrum Berlin für Materialien und Energie, in Germany, has developed a blade-coated perovskite/silicon solar cell that tests at 31.2% efficiency.

In their paper published in the journal Joule, the group describes how they designed, built and tested their cell and their expectations for it going forward.

Prior research has shown that perovskite-silicon tandems can lead to improved efficiencies in solar cells, with some previous research groups seeing efficiency as high as 30%. In this new effort, the research team found that combining them in a new way can lead to even more improvements in efficiency.

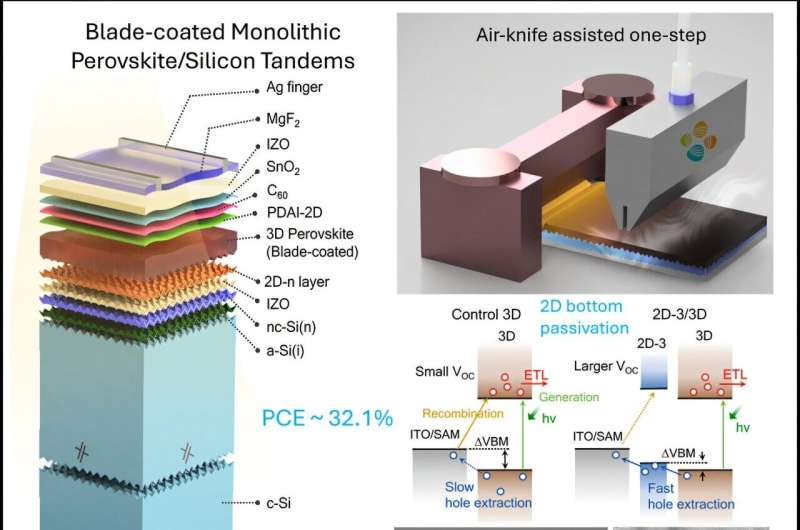

They incorporated 2D layers of perovskite on the bottom of the cell, made possible by the use of scalable, ink-based fabrication—a change also meant to improve stability and the way that solar cells are manufactured.

The researchers chose blade coating rather than spin coating because of scalability factors. This allowed them to deposit a 3D layer of perovskite onto a 2D layer of perovskite in an inverted p-i-n configuration.

They also found that by tuning the 2D film prior to adding the 3D layer, they were able to minimize energy mismatches on the bottom part of the cells. It also helped reduce loss of performance in the coated p-i-n devices.

The team also created a tiny device that was used to stabilize the substrate, which was made of indium tin oxide. They also built an electron transport layer by evaporating buckminsterfullerene and tin oxide. The other layers were made of indium zinc oxide and magnesium fluoride, which served as an anti-reflector. The device was finished off by adding a silver contact.

During testing, the researchers found that the cell could maintain 80% of its peak efficiency for approximately 1,700 hours while exposed to normal sunshine. They suggest their design demonstrates the potential for efficiency gains using scalable ink printing techniques, resulting in products that are both stable and durable. Such an approach, they also note, should also allow for relatively easy manufacturing.

More information: Anand Selvin Subbiah et al, Efficient blade-coated perovskite/silicon tandems via interface engineering, Joule (2024). DOI: 10.1016/j.joule.2024.09.014

Journal information: Joule

Leave a Reply