By Ashwini Sakharkar 14 Oct, 2024

Collected at: https://www.techexplorist.com/quick-easy-way-produce-anode-materials-sodium-ion-batteries/91128/

The research team at the Nano Hybrid Technology Research Center of the Korea Electrotechnology Research Institute (KERI) has achieved a major breakthrough in battery technology. Dr. Daeho Kim and Dr. Jong Hwan Park have developed a revolutionary process that allows for the rapid preparation of hard carbon anodes for sodium-ion batteries in just 30 seconds, using microwave induction heating.

Sodium-ion batteries, the next generation of secondary batteries, offer a promising alternative to lithium-ion batteries. Sodium, a vastly abundant and easily extractable resource, presents a compelling solution to the scarcity and environmental concerns associated with lithium. The stability of sodium also makes it ideal for fast charging and discharging, even in low-temperature conditions.

Despite these advantages, sodium-ion batteries have faced challenges, including lower energy density and a shorter lifespan compared to lithium-ion batteries. The development of this rapid and efficient preparation process for hard carbon anodes addresses these challenges, paving the way for the widespread adoption of sodium-ion batteries.

Hard carbon, a crucial material for sodium-ion batteries, is not naturally occurring and must be synthesized through a highly intricate process. This process involves heating hydrocarbon materials, the main components of plants and polymers, in an oxygen-free environment at temperatures exceeding 1,000°C for extended periods. However, this “carbonization” process is both economically and environmentally burdensome, posing a significant obstacle to the commercialization of sodium-ion batteries.

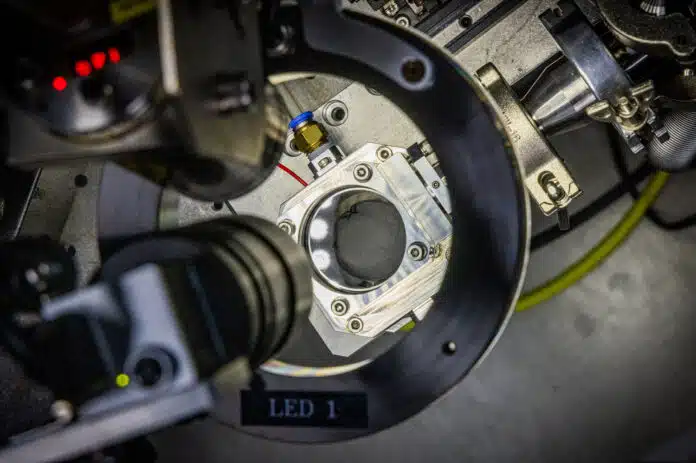

In response to this challenge, a team led by Dr. Kim and Dr. Park has proposed a groundbreaking rapid heating method using microwave technology, readily available from a kitchen microwave oven. The team first developed films by blending polymers with a small amount of highly conductive carbon nanotubes.

Subsequently, they applied a microwave magnetic field to the films to induce currents in the carbon nanotubes, selectively heating the films to over 1,400°C in just 30 seconds. This innovative approach has the potential to revolutionize the synthesis of hard carbon, paving the way for more efficient and cost-effective sodium-ion batteries.

KERI has pioneered a groundbreaking technology for uniformly heat-treating conductive thin films, such as metals, using microwave magnetic fields. This innovation has sparked widespread interest in industrial applications, particularly in the fields of displays and semiconductors. Notably, KERI’s Nano Hybrid Technology Research Center has emerged as the nation’s foremost hub for carbon nanomaterials technology. Dr. Kim and Dr. Park have harnessed the center’s capabilities to delve into sodium-ion battery anode materials, yielding highly promising results.

Their success can be attributed to the team’s pioneering “multiphysics simulation” technique, which has provided deep insights into the intricate processes triggered by the application of an electromagnetic field in the microwave bandwidth to nanomaterials. This has led to the development of an innovative process for preparing sodium-ion battery anode materials.

The paper was co-first-authored by Geongbeom Ryoo and Jiwon Shin, student researchers who participated in KERI’s academia-research collaborative research program.

“Due to recent electric vehicle fires, there has been growing interest in sodium-ion batteries that are safer and function well in colder conditions. However, the carbonization process for anodes has been a significant disadvantage in terms of energy efficiency and cost,” said Dr. Jong Hwan Park. Dr. Daeho Kim added: “Our microwave induction heating technology enables fast and easy preparation of hard carbon, which I believe will contribute to the commercialization of sodium-ion batteries.”

Moving forward, the team is committed to enhancing the performance of their anode materials and advancing technology for the continuous mass production of large-area hard carbon films. Their microwave induction heating technology also holds promise for broader applications, including all-solid-state batteries requiring high-temperature sintering, thus meriting further exploration.

With a domestic patent application already completed, KERI anticipates substantial interest from companies engaged in energy storage materials. They are poised to enter into technology transfer agreements with potential industry partners, leveraging the immense potential of their innovative technology.

Journal reference:

- Gyeongbeom Ryoo et al. Sub-minute carbonization of polymer/carbon nanotube films by microwave induction heating for ultrafast preparation of hard carbon anodes for sodium-ion batteries. Chemical Engineering Journal, 2024. DOI: 10.1016/j.cej.2024.154081

Leave a Reply