By U.S. Department of Energy October 13, 2024

Collected at: https://scitechdaily.com/inside-the-laser-forge-how-3d-printed-superalloys-conquer-extreme-environments/

Scientists have developed a new way to make stronger metals for use in extreme environments like power generation turbines.

By using 3D printing and analyzing the metals with neutron technology, they’ve found that heat treatments can lower the stress within the metals, making them more durable.

Advanced Superalloys

Extreme applications such as advanced gas turbines for electric power generation require equally sophisticated materials. In this research, scientists examined the stress effects in innovative “superalloys” composed of two high-strength, high-heat resistant metals. The team crafted these alloys using 3D printing, a technique that employs lasers to mold metal powder into specified shapes. Subsequently, they utilized neutrons to analyze the internal structure of the printed metals.

The study revealed that heat treatments effectively mitigate stress induced during manufacturing. Additionally, it was found that these stresses are more influenced by specific manufacturing parameters rather than the metal’s chemical composition.

Advancements in 3D-Printed Metal Alloys

The team adeptly employed laser-based 3D printing to fabricate alloys from two distinct metals, Inconel 718 and René 41, without any cracking. Neutron experiments facilitated the development of an enhanced method to accurately and efficiently assess the levels of stress induced in the metals throughout the manufacturing process. The findings will contribute to the production of stronger, more advanced alloys with lower manufacturing costs. These alloys are crucial for applications in extreme environments.

Additive Manufacturing Collaboration

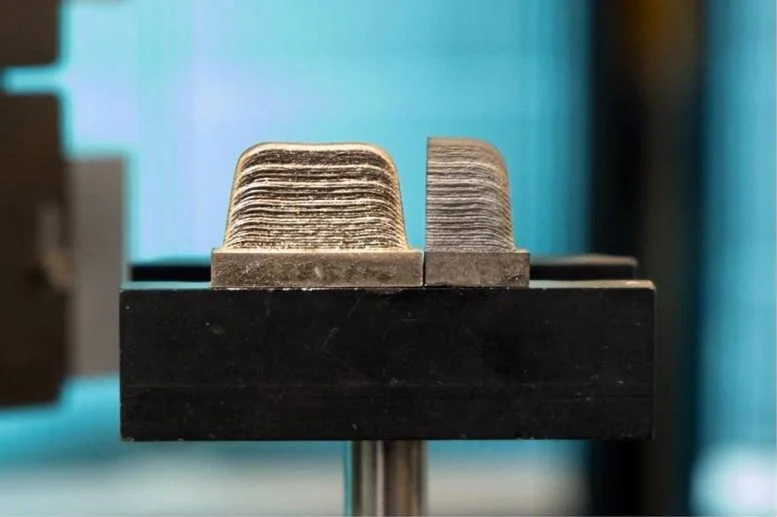

Additive manufacturing, or 3D printing, is a new way of making metal parts and other types of materials by building them layer by layer. This research project, by researchers at General Electric, the Edison Welding Institute, and Oak Ridge National Laboratory (ORNL), printed an alloy composed of Inconel 718 and René 41 at two ends with a compositional graded region in the middle. The study evaluated the stress and composition variations of the alloy. To do so, the researchers conducted neutron experiments at the Spallation Neutron Source (SNS) and the High Flux Isotope Reactor (HFIR) at ORNL, both Department of Energy Office of Science user facilities. Neutrons are ideally suited to study internal stresses in materials because they can penetrate dense metals.

Neutron Analysis of Manufacturing Stresses

Using the VULCAN diffractometer at SNS and the MARS imaging instrument at HFIR, the researchers measured the distribution of residual lattice strains to see how the materials’ residual stresses and compositions changed during different processing phases. The neutron studies revealed that residual stresses occurred mostly as a result of the manufacturing process and can be mitigated by heat treatments. Stresses were found to be worse with longer laser dwell time or higher energy levels. The neutron studies also helped establish a more effective method for the companies to analyze the metals and improve their usefulness for making better parts at lower costs using additive manufacturing.

Reference: “Residual stress and microstructure in IN718-René41 graded superalloy fabricated by laser blown directed energy deposition” by Shenyan Huang, Chen Shen, Ke An, Yuxuan Zhang, Ian Spinelli, Marissa Brennan and Dunji Yu, 1 December 2022, Frontiers in Metals and Alloys.

DOI: 10.3389/ftmal.2022.1070562

This work was supported by the Department of Energy (DOE) Office of Energy Efficiency and Renewable Energy, Advanced Manufacturing Office. A portion of this research used resources at the Spallation Neutron Source and High Flux Isotope Reactor, both DOE Office of Science user facilities operated by the Oak Ridge National Laboratory.

Leave a Reply