By Thomas Burke December 19, 2023

Collected at: https://www.plantengineering.com/articles/how-tsn-helps-manufacturers-enable-edge-computing-capabilities/

High volumes of data are being generated by smart applications and technologies, providing the foundation to create an in-depth understating of equipment status, processes and activities. This can be translated into unique actionable insights to improve productivity, performance and efficiency.

Large datasets are another raw material required by competitive enterprises. But having a solid, reliable infrastructure to share process data, information and knowledge is equally important to succeed. Edge computing also is instrumental to creating frameworks capable of quickly and securely evaluating data.

This technology conducts analytics for real-time decision-making at the periphery of the network, close to where data is being created, while also supporting knowledge generation by filtering what should be sent to the Cloud or other higher-level systems. As a result, the edge can reduce latency and network costs as well as optimize bandwidth usage, increase speed, security and scalability. The edge also can achieve enhanced transparency, flexibility and availability.

At the cutting edge of industrial networks

In order to take advantage of all the opportunities offered by edge computing, setting up a suitable network that can support key aspects of this technology is critical.

An ideal industrial communications system should support a converged architecture that allows real time process traffic and asynchronous process data to share the same network without compromising the overall function of the system. This is achieved with a foundation of determinism, ensuring all data types flow across the network in a predictable manner to deliver the required performance.

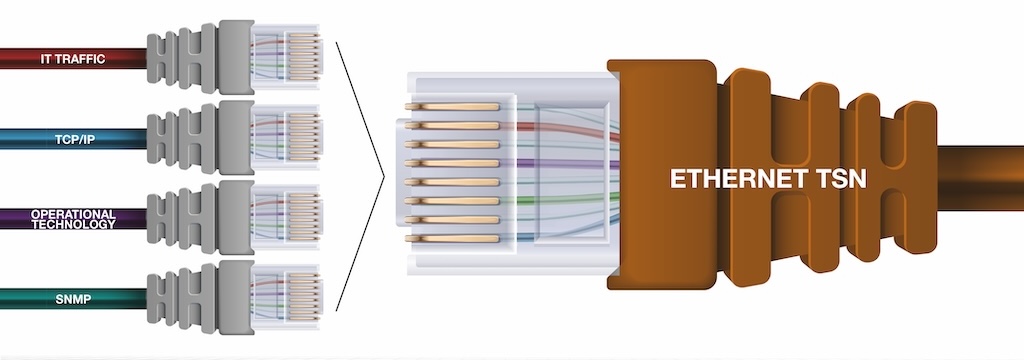

Time-sensitive networking (TSN) can help deliver a converged and deterministic architecture. It allows the critical data running the process to coexist with the critical, but perhaps less time-sensitive, data about the process. It is this latter data type that is the lifeblood of the edge server. Using TSN lets these different, but equally vital, streams of traffic use a single network architecture. This helps reduce costs, simplifies maintenance and reduces project time.

The CC-Link network with TSN enables operational technology as well as IT and other communication networks to exist on a single Ethernet cable, which supports more reliable communication. Courtesy: CC Link Partner Association

Companies should look for an open solution that can provide maximum connectivity. This means supporting communications with different devices, whether on the shop floor or higher up in the automation hierarchy. Openness, interoperability, and an integrated solution for automation on different levels are therefore essential.

The CLPA can help enable network technologies for edge applications. This began with open gigabit industrial Ethernet. By leveraging a token-passing method and 1 Gbit/s bandwidth. The different versions of these Ethernet networks, which supplement each other and cover different aspects of industrial communications, could connect the various parts of an enterprise needed to create connected industries.

There are even further advancements in the ability to support edge computing, enhancing and expanding the capabilities of this solution. TSN-compatible components, businesses can gain a unique, competitive edge in the marketplace.

Leave a Reply