By Chris Vavra March 13, 2024

Collected at: https://www.plantengineering.com/articles/how-ai-ml-can-help-design-future-proof-material-handling-facilities/

Material handling facilities are getting more sophisticated than ever, but the right data is needed to ensure their future growth. Artificial intelligence (AI) and machine learning (ML) can help in that evolution, said Christopher Connelly, business development manager at O’Neal LLC and Billy Few, instrumentation and controls department head at Bridge Automation LLC, in their presentation “Designing Futureproof Material Handling Facilities” at Modex in Atlanta.

AI can take over some tasks that typically require human intelligence and ML allows software applications to become more accurate in predicting outcomes without being explicitly programmed. ML models, as a result, can identify patterns and grow as the system is exposed to more information.

This can help predictive maintenance systems improve visual monitoring, which is an AI process, as well as ML models that learn from tabular data collected from sensors and machines.

Christopher Connelly (left), business development manager at O’Neal LLC and Billy Few, instrumentation and controls department head at Bridge Automation LLC, in their presentation “Designing Futureproof Material Handling Facilities” at Modex in Atlanta. Courtesy: Chris Vavra, CFE Media and Technology

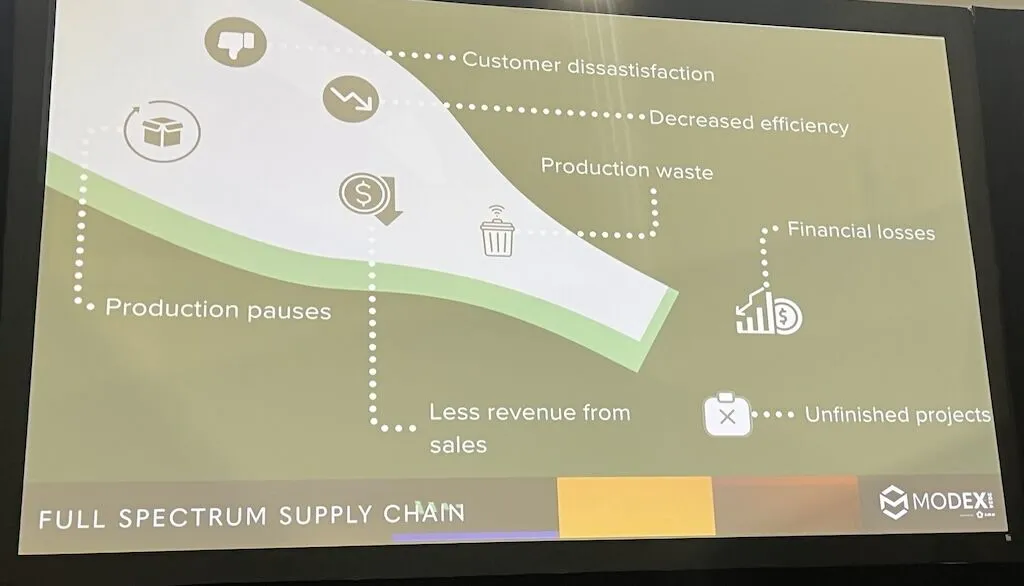

Few said this information can help future-proof facilities by reducing production pauses, waste and increasing overall efficiency. He said they try to solve problems and future-proof their operations with generative AI. They start with a large language model (LLM), which is trained to understand human language. From there, it goes into a vector database, which is multi-dimensional and clustered and tied to similarities.

Few said the data is gathered differently from the way a human might do. He used a wine cellar as an example. A regular person might put wines together by color or type or through some basic preference a human can identify with. A vector database, by contrast, is more like having a sommelier grouping the wines. It’s based on a level of deep expertise that goes beyond simple preferences and groupings.

With a vector database, it can gather all the information and make better and more informed decisions. However, Few cautioned the output is only as good as the data put into the system.

“If you don’t have good data, it might take a little longer to get the good data you need,” he said. He advised companies start small and tackle pain points that have big return on investments (ROIs).

Industry 4.0, of which AI/ML is a part, can offer many benefits, but so many companies, Few said, are on that journey. Many, he said, haven’t considered implementing or haven’t gotten out of the conceptual process. Fewer have a plan in place and haven’t implemented it yet. Some have begun or completed the project, but they are the outlier.

Those still in the thinking or planning phase can get started with an Industry 4.0 audit, which consists of five steps:

- Start with problems or deficiencies you’re experiencing

- Identify specific goals you have in mind

- Conduct a facility audit to investigate

- Complete a full study with a tailored Industry 4.0 roadmap

- Identify and prioritize high ROI projects.

Strategies for a successful project

Connelly said future-proofing a material handling facility starts with identifying areas a vector database might help with such as:

- Material flow optimization

- Improved storage algorithms

- Inventor levels and minimum reorder points

- Demand forecasts

- Optimized traffic management

- Optimized package sizes.

A plan should be developed with understanding key interface points between the owner, automation integrator, general contractor and the other trades involved in the project.

A good project, Connelly said, needs proper planning and setup during the early phases with a clear of delineation of responsibility. This helps establish a concrete road map to success with everyone aligned.

Few said the information gathered from AI and ML can help future-proof facilities by reducing production pauses, waste and increasing overall efficiency. Courtesy: Chris Vavra, CFE Media and Technology

Connelly also recommended identifying the key stakeholders and develop a specific execution strategy and logistics schedule and to stay engaged through commissioning, start-up and acceptance testing.

If the project doesn’t have buy-in from all parties, then it doesn’t matter how much planning or thought went into it. All it will end up being is a massive waste of everyone’s time and energy.

Leave a Reply