Michal Lewinsohn – August 22, 2024

Collected at: https://www.iotforall.com/iot-trends-in-manufacturing-from-smart-to-virtual

From the early 1900s to the 2000s, the manufacturing industry underwent significant innovation, beginning with lean manufacturing that introduced efficient assembly line production and specialized machinery tailored for specific tasks.

Moving into the 2000s, the focus shifted towards the “smart factory,” integrating connected devices and automation to enhance equipment effectiveness and employing predictive maintenance to avoid failures.

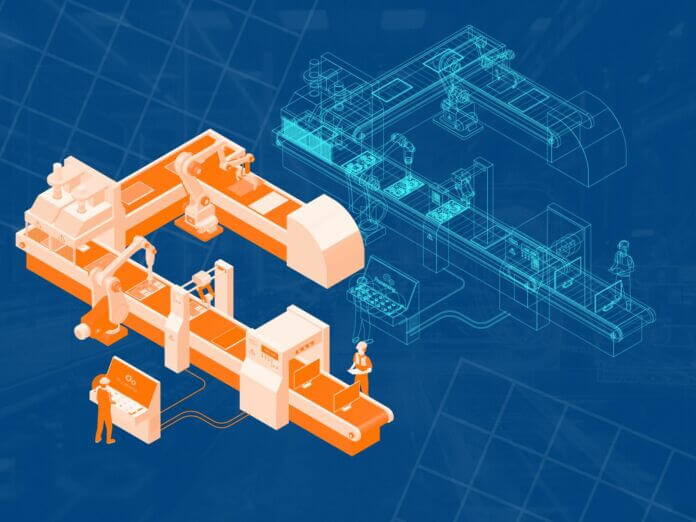

The next 5–10 years will see digital factories with autonomous operations, leveraging digital twins for smart, risk-free optimization.

But for this innovation to occur at scale, IoT teams in manufacturing need to be aware of the trends, pitfalls, and best practices in this evolving space. This article defines IoT, explores manufacturing trends, IoT pain points, and offers best practices for implementation.

What is IoT?

The Internet of Things (IoT) is a network of physical objects with sensors and software exchanging data online. These devices range from ordinary household objects to sophisticated industrial tools.

IoT in Manufacturing

In the manufacturing industry, IoT often comes in the form of industrial robots and machinery on the factory floor. Advanced connected devices need frequent updates, becoming bigger targets for attackers, increasing demands on management teams.

As outlined above, the landscape of manufacturing has undergone significant transformations over the past century. The introduction of IoT marks a key phase of innovation.

Key Market & IoT Tech Trends in Manufacturing

Zooming in on the technological trends in the manufacturing market today and shortly, we see the following patterns emerge:

- Digital transformation accelerates: Factories are moving from smart to a virtual industrial metaverse with heavy utilization of immersive technologies such as AR/VR. Manufacturers are moving from simply having visibility into big data toward discovering the benefits of big data using AI/ML.

- AI-powered devices, sensors, and robotics: Gartner speculates that by 2028, there will be more smart robots than frontline workers in manufacturing. In-device software is scaling up with increasing complexities, dependencies, and embedded machine learning (ML) models. “Things” now require more frequent updates.

- Gaps in cybersecurity: Manufacturing is one of the sectors most targeted by cyberattacks. Exploited software vulnerabilities are the 2nd-largest attack vector, representing ~24 percent of all incidents. To adequately combat and prevent these attacks, manufacturers require software curation and software supply chain security practices.

- Manufacturing in Cloud: Manufacturers are shifting to the cloud, adopting SaaS, containerizing software for scalability, and enhancing security strategies. And they tend to prefer cloud-agnostic software that reduces vendor lock-in.

- Intelligent edge: Computer vision systems and autonomous robotics generate massive amounts of multi-dimensional data. Gartner predicts that in 2025, more than 50 percent of enterprise data will be both created and processed outside the data center or cloud at the edge.

- Digital twin technologies trending as virtual factory enablers: A digital twin is a virtual replica of physical objects or systems, enabling simulations, virtual prototypes, and testing. Over 70 percent of businesses don’t have a digital twin strategy in place for IoT devices.

IoT Pain Points in Manufacturing

Manufacturers struggle in three key areas to keep pace with the evolving IoT landscape due to industry changes.

- Slow and costly time to market: Just like mainstream applications, edge devices are evolving rapidly, becoming increasingly software-driven and intelligent. This shift has led to more frequent software updates, which introduces both operational challenges and additional costs; updating devices that are often difficult to access due to their physical location or lack of external IP addresses can be particularly cumbersome and expensive.

- Security risks: As the frequency of updates increases, so does the exposure of these devices to potential security threats. Managing and monitoring software on edge devices is crucial, especially in critical environments like manufacturing lines, vehicles, and aircraft. Edge device failures in critical settings can have far more severe consequences than a typical server malfunction.

- Operational limits and inefficiencies: Companies typically source their devices from various vendors, which makes device management more complex. To effectively oversee a diverse array of devices, organizations need comprehensive visibility into their entire fleet. This includes understanding which devices are updated and what software is running on each device. Digital twins offer detailed software representations, aiding in addressing security and operational needs for devices. A lack of clear software inventories or a unified SBOM complicates managing and securing software.

Companies must navigate these challenges to ensure robust and secure operations across their network of edge devices. One of the most effective ways to address these challenges is by choosing a universal platform for managing your IoT software releases. It’s estimated that 75 percent of organizations will have switched from multiple-point solutions to platforms to streamline application delivery by 2025 – that’s up from 25 percent in 2023.

Manufacturing & IoT

The integration of IoT in the manufacturing industry has entirely revolutionized how operations are conducted, transitioning from lean manufacturing to smart factories and now to virtual factories. As these technologies continue to evolve, managing and securing fleet device software becomes increasingly critical.

Manufacturers must stay ahead of trends like AI-powered devices, digital twins, and cloud computing while addressing cybersecurity gaps and operational inefficiencies. By adopting universal platforms for IoT software management, manufacturers can streamline their operations, enhance security, and remain competitive in this rapidly changing landscape.

Leave a Reply