By Ashwini Sakharkar 20 Jun, 2024

Collected at: https://www.techexplorist.com/new-class-materials-very-hard-difficult-break/85354/

Glassy polymers are generally stiff and strong yet have limited extensibility. These polymers are used to make things like water bottles or airplane windows. Gels – such as contact lenses – contain liquid and are soft and stretchy.

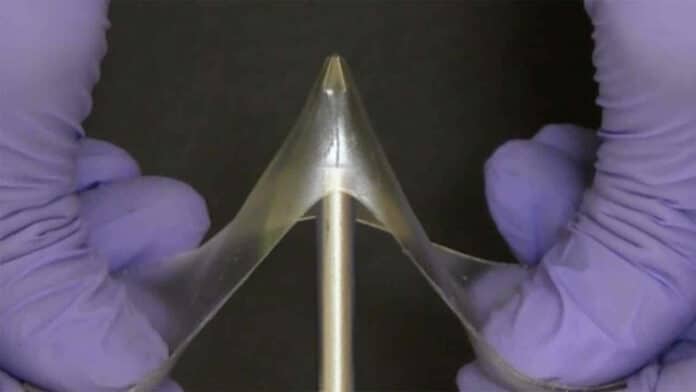

Now, researchers at the North Carolina State University have created a new class of materials called “glassy gels” that are very hard and difficult to break despite containing more than 50% liquid.

The innovation of glassy gels represents a significant advancement in material science, merging the properties of gels and glassy polymers to create a new class of materials that are both hard and flexible. Simple to produce, this glassy gel holds promise for a variety of applications.

“We’ve created a class of materials that we’ve termed glassy gels, which are as hard as glassy polymers, but – if you apply enough force – can stretch up to five times their original length rather than breaking,” says Michael Dickey, corresponding author of a paper on the work and the Camille and Henry Dreyfus Professor of Chemical and Biomolecular Engineering at North Carolina State University. “What’s more, once the material has been stretched, you can get it to return to its original shape by applying heat. In addition, the surface of the glassy gels is highly adhesive, which is unusual for hard materials.”

“A key thing that distinguishes glassy gels is that they are more than 50% liquid, which makes them more efficient conductors of electricity than common plastics that have comparable physical characteristics,” says Meixiang Wang, co-lead author of the paper and a postdoctoral researcher at NC State.

“Considering the number of unique properties they possess, we’re optimistic that these materials will be useful,” Wang says.

As the name suggests, glassy gels are effectively a material that combines some of the most attractive properties of both glassy polymers and gels. The process of creating glassy gels involves mixing liquid precursors of glassy polymers with an ionic liquid and then curing the mixture with ultraviolet light. This results in a material that is tough and stretchable and has the unique ability to return to its original shape when heat is applied.

“The ionic liquid is a solvent, like water, but is made entirely of ions,” says Dickey. “Normally, when you add a solvent to a polymer, the solvent pushes apart the polymer chains, making the polymer soft and stretchable. That’s why a wet contact lens is pliable and a dry contact lens isn’t. In glassy gels, the solvent pushes the molecular chains in the polymer apart, which allows it to be stretchable like a gel. However, the ions in the solvent are strongly attracted to the polymer, which prevents the polymer chains from moving. The inability of chains to move is what makes it glassy. The end result is that the material is hard due to the attractive forces but is still capable of stretching due to the extra spacing.”

Researchers also found that glassy gels could be made with a variety of different polymers and ionic liquids, though not all classes of polymers can be used to create glassy gels. “Polymers that are charged or polar hold promise for glassy gels because they’re attracted to the ionic liquid,” Dickey says.

During testing, it was found that the glassy gels don’t evaporate or dry out, even though they consist of 50-60% liquid. “Maybe the most intriguing characteristic of the glassy gels is how adhesive they are,” says Dickey. “Because while we understand what makes them hard and stretchable, we can only speculate about what makes them so sticky.”

Moreover, the adhesive quality of the surface of glassy gels opens up potential uses in various fields, from medical devices to electronics, where durable and flexible materials are essential.

“Creating glassy gels is a simple process that can be done by curing it in any type of mold or by 3D printing it,” says Dickey. “Most plastics with similar mechanical properties require manufacturers to create polymer as a feedstock and then transport that polymer to another facility where the polymer is melted and formed into the end product. We’re excited to see how glassy gels can be used and are open to working with collaborators on identifying applications for these materials.”

Journal reference:

- Meixiang Wang, Xun Xiao, Salma Siddika, Mohammad Shamsi, Ethan Frey, Wen Qian, Wubin Bai, Brendan T. O’Connor & Michael D. Dickey. Glassy gels toughened by solvent. Nature, 2024; DOI: 10.1038/s41586-024-07564-0

Leave a Reply