24 May, 2024 by Amit Malewar

Collected at : https://www.techexplorist.com/sensor-electronic-spider-silk-imprinted-skin/84223/

Despite the extraordinary sensitivity of human skin, adding electronic sensors to it could completely alter how we interact with the environment. Directly printed sensors on the skin, for instance, could be utilized for ongoing health monitoring, comprehending skin sensations, or enhancing the sense of “reality” in virtual reality or gaming applications.

Smartwatches and other wearables with embedded sensors are commonplace, yet they can also be intrusive, uncomfortable, and interfere with the skin’s natural senses.

The device-surface interaction is critical to accurately sensing anything on a biological surface, such as skin or a leaf.

Scientists have created a technique for direct, imperceptible printing of environmentally friendly, adaptive sensors onto various biological surfaces, such as a flower petal or a finger.

The technique was created by University of Cambridge researchers and is modeled after spider silk, which can adhere to a variety of surfaces. Bioelectronics is also incorporated into these “spider silks” to expand the “web’s” sensing capabilities.

The fibers are so light—at least 50 times thinner than human hair—that the researchers could print them straight onto a dandelion’s fluffy seedhead without causing the structure to collapse.

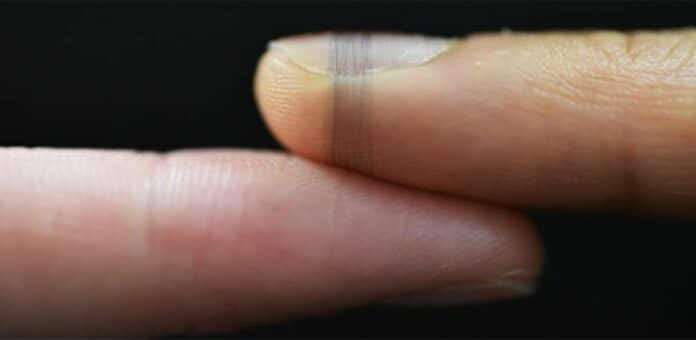

When printed on the fiber sensors, they adapt to human skin, exposing the sweat pores so the person is unaware of their existence. The fibers printed onto a human finger have undergone tests that indicate they may find utility as continuous health monitors.

This low-emission, low-waste approach to enhancing living structures has applications in virtual reality, healthcare, electronic textiles, and environmental monitoring, among other areas.

This innovative method of printing high-performance bioelectronics directly onto biological surfaces, such as dandelion seedheads or fingertip surfaces, allows for customization.

Using PEDOT:PSS, a biocompatible conducting polymer, hyaluronic acid, and polyethylene oxide, the researchers spun their bioelectronic “spider silk.” Because the high-performance fibers were made at room temperature from a water-based solution, the researchers could regulate the fibers’ “spinnability.” Subsequently, researchers devised an orbital spinning methodology to enable the fibers to adapt to living surfaces, including microstructures like fingerprints.

The bioelectronic fibers demonstrated superior sensor performance while remaining undetectable to the host in tests conducted on various surfaces, such as human fingers and dandelion seedheads.

Andy Wang, the first author of the paper, said, “Our spinning approach allows the bioelectronic fibers to follow the anatomy of different shapes, at both the micro and macro scale, without the need for any image recognition. It opens up a whole different angle regarding how sustainable electronics and sensors can be made. It’s a much easier way to produce large area sensors.”

Most high-resolution sensors are manufactured in industrial cleanrooms using hazardous chemicals in a labor-intensive, multi-step procedure. Cambridge’s sensors can be manufactured anywhere and consume very little energy compared to conventional sensors.

Compared to a standard single load of laundry, which generates between 600 and 1500 milligrams of fiber waste, bioelectronic fibers are repairable, can be easily washed away when their useful lives are ending, and produce less than a single milligram of trash.

Yan Yan Shery Huang, who led the research from Cambridge’s Department of Engineering, said, “Using our simple fabrication technique, we can put sensors almost anywhere and repair them where and when they need it, without needing a big printing machine or a centralized manufacturing facility. These sensors can be made on-demand, right where needed, and produce minimal waste and emissions.”

Researchers noted, “Their devices could be used in applications from health monitoring and virtual reality to precision agriculture and environmental monitoring. In the future, other functional materials could be incorporated into this fibre printing method to build integrated fibre sensors for augmenting living systems with display, computation, and energy conversion functions. The research is being commercialized with the support of Cambridge Enterprise, the University’s commercialization arm.”

Journal Reference:

- Wenyu Wang et al. ‘Sustainable and imperceptible augmentation of living structures with organic bioelectronic fibres.’ Nature Electronics (2024). DOI: 10.1038/s41928-024-01174-4

Leave a Reply