MAY 15, 2024 by RMIT University

Collected at : https://techxplore.com/news/2024-05-green-concrete-recycle-coal-ash.html

New modeling reveals that low-carbon concrete developed at RMIT University can recycle double the amount of coal ash compared to current standards, halve the amount of cement required and perform exceptionally well over time.

More than 1.2 billion metric tons of coal ash were produced by coal-fired power plants in 2022. In Australia, it accounts for nearly a fifth of all waste and will remain abundant for decades to come, even as we shift to renewables.

Meanwhile, cement production makes up 8% of global carbon emissions and demand for concrete—which uses cement as a key ingredient—is growing rapidly.

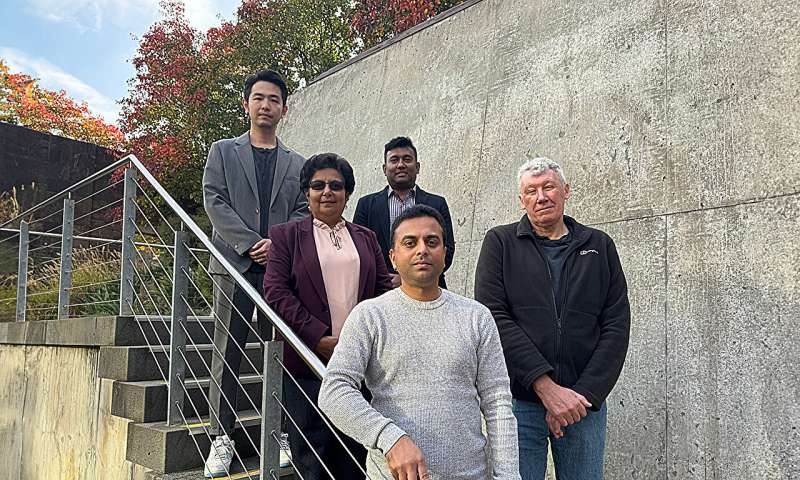

Addressing both challenges head-on, engineers at RMIT have partnered with AGL’s Loy Yang Power Station and the Ash Development Association of Australia to substitute 80% of the cement in concrete with coal fly ash.

RMIT project lead Dr. Chamila Gunasekara said this represents a significant advance as existing low-carbon concretes typically have no more than 40% of their cement replaced with fly ash.

“Our addition of nano additives to modify the concrete’s chemistry allows more fly ash to be added without compromising engineering performance,” said Gunasekara, from RMIT’s School of Engineering.

Finding new opportunities in overlooked pond ash

Comprehensive lab studies have shown the team’s approach is also capable of harvesting and repurposing lower grade and underutilized “pond ash”—taken from coal slurry storage ponds at power plants—with minimal pre-processing.

Large concrete beam prototypes have been created using both fly ash and pond ash and shown to meet Australian Standards for engineering performance and environmental requirements.

“It’s exciting that preliminary results show similar performance with lower-grade pond ash, potentially opening a whole new hugely underutilized resource for cement replacement,” Gunasekara said.

“Compared to fly ash, pond ash is underexploited in construction due to its different characteristics. There are hundreds of megatonnes of ash wastes sitting in dams around Australia, and much more globally.”

“These ash ponds risk becoming an environmental hazard, and the ability to repurpose this ash in construction materials at scale would be a massive win.”

New modeling technology shows low-carbon concrete’s long-term resilience

A pilot computer modeling program developed by RMIT in partnership with Hokkaido University’s Dr. Yogarajah Elakneswaran has now been used to forecast the time-dependent performance of these new concrete mixtures.

According to Dr. Yuguo Yu, an expert in virtual computational mechanics at RMIT, a longstanding challenge in the field has been to understand how newly developed materials will stand the test of time.

“We’ve now created a physics-based model to predict how the low-carbon concrete will perform over time, which offers us opportunities to reverse engineer and optimize mixes from numerical insights,” Yu explained.

This pioneering approach—recently unveiled in the journal Cement and Concrete Research—reveals how various ingredients in the new low-carbon concrete interact over time.

“We’re able to see, for example, how the quick-setting nano additives in the mix act as a performance booster during the early stages of setting, compensating for the large amounts of slower-setting fly ash and pond ash in our mixes,” Gunasekara says.

“The inclusion of ultra-fine nano additives significantly enhances the material by increasing density and compactness.”

This modeling, with its wide applicability to various materials, marks a crucial stride towards digitally assisted simulation in infrastructure design and construction.

By leveraging this technology, the team aims to instill confidence among local councils and communities in adopting novel low-carbon concrete for various applications.

More information: Yuguo Yu et al, Unified hydration model for multi-blend fly ash cementitious systems of wide-range replacement rates, Cement and Concrete Research (2024). DOI: 10.1016/j.cemconres.2024.107487

Leave a Reply